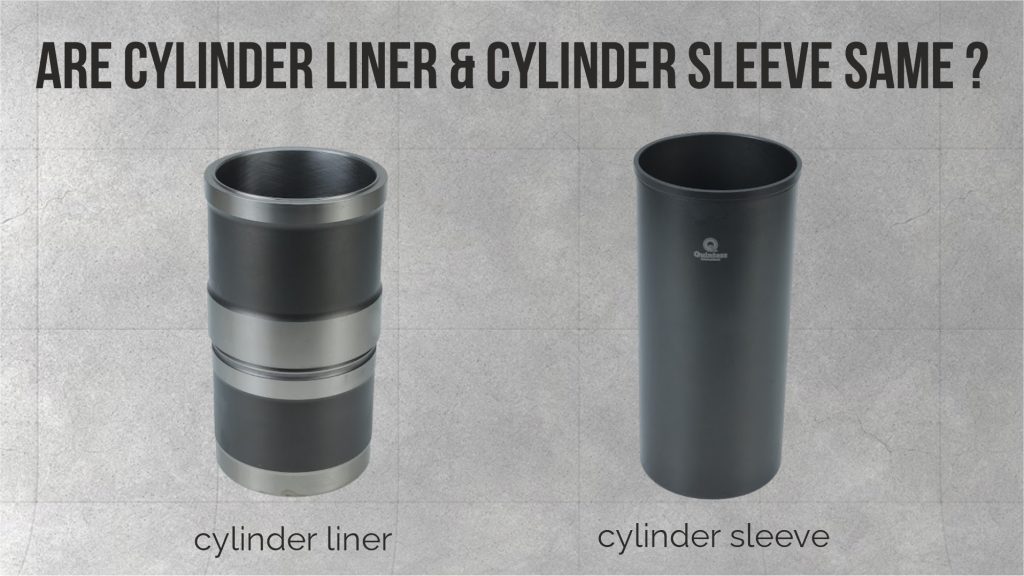

When it comes to engine components, cylinder liners and sleeves are frequently confused for one another, leading novice and experienced engine builders alike to ask if they truly serve similar functions. Though both serve similar roles within an engine’s combustion cycle, there are key distinctions that need to be understood for proper functioning of both. In this blog we will highlight those distinctions along with their roles within it.

What Are Engine Liners and Sleeves?

Engine liners and sleeves are cylindrical inserts placed within an engine block, serving to form the surface in which pistons move up and down under tremendous pressure and heat. Their primary role is to allow pistons to function as intended despite this immense strain and heat.

Liners: Liners are removable inserts designed to fit into an engine block. Common applications for this technology are heavy-duty engines such as trucks, marine engines and industrial applications, where liners allow easy replacement without needing to replace an entire block.

Sleeves: Sleeves can be installed into a cylinder bore by press-fitting them in. Once in place, these permanent solutions can restore original dimensions if the bore becomes damaged or worn out.

Are Liners and Sleeves Compatible?

While “liners” and “sleeves” often refer to similar components in an engine, these terms do not always correspond. While both have similar functions–protecting cylinder bores from wear and tear–their methods of installation and applications often differ significantly.

Replaceability: Liners tend to be easier for large engines to change out than sleeves due to special machining, while sleeves often remain permanent unless specially altered with special tools. Application: Liners tend to be found more in industrial or high-performance engines while sleeves are often more common among mass produced models.

Liners and sleeves are generally constructed from centrifugally cast iron, while sleeves may be constructed using advanced materials such as aluminum alloys depending on engine specifications.

Liners and Sleeves Offer Benefits to Engine Owners and Maintainers

When it comes to ensuring the longevity and efficiency of an engine, cylinder liners and sleeves play a critical role. These components not only protect the engine block but also make maintenance more manageable and cost-effective. Here’s how liners and sleeves benefit engine owners and maintainers:

- Engine Life Extension

Liners and sleeves act as a protective barrier, preventing wear and tear on the engine block. Over time, pistons generate tremendous heat and pressure, which can damage the cylinder bore. By replacing a worn-out liner or sleeve, the engine can be restored to optimal performance without the need for a complete overhaul.

- Cost-Effective Repairs

For engines with damaged or worn bores, sleeves provide an affordable repair solution. Instead of replacing the entire engine block, a sleeve can restore the cylinder to its original specifications. Liners, particularly in heavy-duty applications, allow for quick and straightforward replacements, minimizing downtime and repair costs.

- Improved Durability

High-quality materials like centrifugally cast iron and advanced aluminum alloys ensure that liners and sleeves withstand extreme conditions. Their resistance to wear, corrosion, and high temperatures makes them essential for long-lasting engine performance, even in demanding applications like marine or industrial engines.

Liners and sleeves both help reduce maintenance costs over time, here’s why:

Engine Life Extension: Installing a liner or sleeve can extend engine life while keeping costs to a minimum. Sleeves provide cost-effective cylinder repairs while liners offer an easy replacement option in larger engines.

Improved Durability: High-grade materials like cast iron and aluminum offer enhanced resistance against wear, corrosion and high temperatures, thus increasing durability.

Machine Shop Wisdom on Holes: Machinists often say that “a hole is just a hole,” but in regards to engines it becomes much more significant. Cylinder bore tolerances, material selection and treatment all play an integral part of an engine’s performance and durability.

Precision is key: Liners and sleeves are precision-machined to tight tolerances. Any misinstallation or misalignment could lead to reduced compression levels, overheating issues or even complete engine failure if they’re installed incorrectly.

Material Matters: When choosing between cast iron, ductile iron, and advanced aluminum alloy for engine components, thermal properties play an integral role in their performance and pressure tolerance, particularly under high-stress conditions.

Why Choose Quality Liners and Sleeves?

Choosing high-quality liners and sleeves ensures that engines remain efficient, durable, and cost-effective over time. A well-maintained engine not only saves on operational costs but also prevents unexpected failures, ensuring smooth operations for engine owners and maintainers alike.

Looking for reliable and durable engine liners and sleeves? Anand Liners (India) Pvt. Ltd. specializes in providing top-quality solutions for all engine types.

Explore our range of products today: Visit Quintess International

Would you like me to expand this into a blog or adjust it further?