Cylinder block sleeves play a crucial role in engine performance and longevity. They are an integral part of engine maintenance and repair.

These sleeves, often made from cast iron or steel, protect the engine block. They also extend the life of an engine, making them a cost-effective solution for repairs.

In this guide, we will delve into the benefits of using cylinder block sleeves. We’ll explore how they enhance engine performance, contribute to cost-effective repairs, and offer environmental benefits.

Whether you’re an automotive enthusiast, a professional mechanic, or a vehicle owner, this guide will provide valuable insights into the importance of cylinder block sleeves.

Understanding Cylinder Block Sleeves

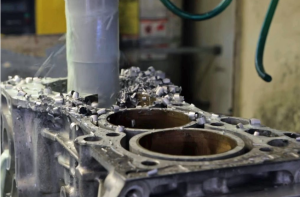

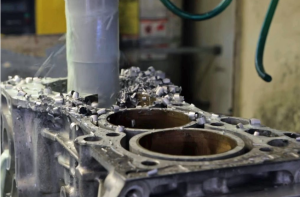

Cylinder block sleeves, or engine cylinder sleeves, are crucial components within an engine. They serve as replaceable surfaces for the engine pistons. Their role is vital in maintaining optimal engine function and durability.

These sleeves are typically crafted from robust materials like cast iron or steel. These materials offer excellent wear resistance and durability, ensuring long-lasting performance. The choice of material can greatly influence the sleeve’s performance and the engine’s longevity.

There are two main types of cylinder sleeves: wet and dry. Wet cylinder sleeves have direct contact with engine coolant, enhancing heat dissipation. On the other hand, dry sleeves fit snugly within the cylinder block, providing a simple replacement option without direct cooling.

Both wet and dry sleeves provide unique advantages. Wet sleeves offer better cooling efficiency, while dry sleeves offer easy installation and replacement. Choosing the right type depends on specific engine requirements and operational conditions.

Advantages of Cylinder Block Sleeves for Engine Performance

Cylinder block sleeves play a significant role in enhancing engine longevity. By providing a replaceable surface for pistons, they minimize wear on the engine block. This extension in engine life is a major advantage for vehicle owners.

A key benefit of cylinder block sleeves is their ability to improve heat dissipation. This is especially true for wet sleeves, which interact directly with engine coolant. Effective heat management protects the engine from overheating.

Wear and corrosion resistance are critical features of cylinder block sleeves. Made from durable materials like steel, they withstand harsh engine conditions. This durability ensures reliable performance over time.

Customization is another advantage offered by cylinder sleeves. They can be tailored to fit specific engine needs, ensuring a precision fit. This customization enhances engine performance and efficiency.

Cylinder block sleeves perform exceptionally well under high-pressure situations. High-performance and racing engines often rely on these sleeves. Their ability to maintain structural integrity under stress ensures smooth operation.

Here are some key performance advantages:

- Longevity: Extends the life of engine components.

- Heat Dissipation: Prevents overheating and enhances engine cooling.

- Durability: Offers strong resistance to wear and corrosion.

- Customization: Allows for precise fitting and tuning.

- High-Pressure Performance: Suitable for demanding engine applications.

Utilizing cylinder sleeves provides these performance benefits, making them indispensable for engine maintenance and optimization.

Cylinder Block Sleeves as a Cost-Effective Repair Solution

Another advantage of cylinder sleeves is their ability to restore engine cylinder dimensions. Over time, engines may experience wear that alters their dimensions. Cylinder block sleeves provide a practical solution for this issue.

Bore repairs and engine overhauls become simpler with cylinder block sleeves. They eliminate the need for complex and expensive machining processes. Installing sleeves simplifies the repair process and reduces downtime.

Here’s a quick list of their cost-effective benefits:

- Cost Savings: Avoids the high expense of complete engine replacements.

- Restoration: Returns engine cylinders to their original specifications.

- Ease of Repair: Streamlines bore repair and overhaul tasks.

By incorporating cylinder sleeves, you can significantly reduce repair costs while enhancing engine functionality. This makes them a wise investment for any engine repair project.

Installation and Maintenance of Cylinder Sleeves

Choosing high-quality materials for cylinder sleeves is essential. Durable materials like cast iron or steel offer superior wear resistance. These materials, combined with proper lubrication, enhance sleeve longevity and engine performance.

Maintenance involves regular checking of lubrication levels and conditions. Proper lubrication minimizes friction between the sleeves and pistons, protecting both components. Routine maintenance keeps the engine running smoothly and extends its lifespan.

Cylinder block sleeves are versatile and can be fitted in different engine types. Whether it’s a diesel, petrol, or a high-performance engine, sleeves can be tailored to meet specific needs. This adaptability makes them an attractive choice for various applications.

Considerations for installation and maintenance include:

- Professional Installation: Guarantees proper fit and functionality.

- Material Selection: Ensures durability with cast iron or steel sleeves.

- Lubrication Management: Maintains engine health through proper lubrication.

These factors highlight the importance of professional installation and ongoing maintenance. By paying attention to these details, you ensure that your engine operates at its best.

The Impact of Cylinder Sleeves on Engine Value and Longevity

Cylinder sleeves can significantly boost a vehicle’s resale value. Potential buyers are often attracted to vehicles with well-maintained engines. The presence of cylinder sleeves indicates a commitment to engine care and longevity.

Installing cylinder sleeves can be invaluable for classic and older engines. Many of these engines are no longer in production, making parts scarce. Sleeves allow for continued operation by restoring worn cylinders to their original dimensions.

In high-performance and racing engines, cylinder sleeves prove essential. They enhance the engine’s ability to handle increased stresses and pressures. This leads to improved horsepower, torque, and overall performance.

Consider how cylinder sleeves contribute to engine value and longevity:

- Resale Value: Enhances market appeal and potential selling price.

- Classic Engines: Extends the functional life of older models.

- Racing Performance: Improves engine capacity to perform under pressure.

In summary, cylinder sleeves provide both financial and operational advantages. They maximize engine life while maintaining or even increasing vehicle value. This dual benefit makes them an intelligent investment for any vehicle owner.

Conclusion

Cylinder block sleeves offer numerous advantages for engine maintenance and performance. They enhance engine longevity, restore cylinder dimensions, and provide resistance to wear and corrosion. Additionally, they contribute to environmental sustainability and are cost-effective for repairs.

Investing in cylinder block sleeves is a smart decision for any vehicle owner. Their benefits go beyond repairs, ensuring smooth engine operations and potentially increasing the vehicle’s value. With the right installation and maintenance, these sleeves are a vital component for engine health and performance.