At Quintess International, we understand that, indeed, the foundation of a reliable engine lies in the quality of its components. Among these, engine bearings, in particular, play a crucial role in ensuring smooth operation and longevity. Whether you’re in the automotive, industrial, or marine sectors, you, without a doubt, rely on engine bearings to keep your machinery running efficiently. In this blog, therefore, we’ll explore the importance of engine bearings and how Quintess International, consequently, delivers top-tier solutions to meet your needs.

The Role of Engine Bearings in Your Engine

Despite their little size, engine bearings are essential. These elements are positioned in a deliberate manner between an engine’s rotating components, such the connecting rods and crankshaft, in order to lower friction and assist the engine’s rotation. Engine failure would ensue from severe wear, heat production, and metal-to-metal contact in the absence of engine bearings.

Our Product Range

At Quintess International, we offer a comprehensive range of engine bearings to suit various applications:

Main Bearings: Firstly, they are designed to support the crankshaft and ensure smooth rotation within the engine block. Notably, our main bearings are known for their high load-carrying capacity and excellent durability.

Rod Bearings: In addition, connecting the crankshaft to the connecting rods, our rod bearings facilitate smooth motion and efficient energy transfer. Furthermore, they are built to withstand the intense forces generated during engine operation.

Camshaft Bearings: Moreover, essential for the proper operation of your engine’s valve system, our camshaft bearings ensure precise timing and smooth rotation.

Thrust Bearings: Lastly, preventing axial movement of the crankshaft, our thrust bearings ensure your engine’s components remain properly aligned, thereby reducing wear and extending engine life.

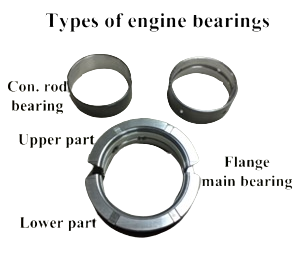

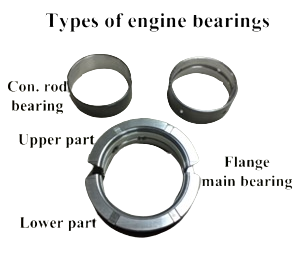

Types of Engine bearing

- Rod Bearing: This is the bearing that slides between the crankshaft and connecting rod, minimising friction and enabling smooth rotation of the rod.

- Upper Part: This probably refers to the portion of a split bearing that would be used to support the crankshaft inside the engine block.

- Lower Part: The lower half of a split bearing, on the one hand, works in conjunction with the upper part; consequently, it fully encases the crankshaft, thereby providing support and, in turn, reducing friction during rotation.

- Flange Main Bearing: A type of bearing that supports the crankshaft while, consequently, preventing its axial movement. Moreover, it is often used in the main journals of the engine to effectively control endplay.