The optimal functioning of your vehicle relies heavily on the crucial role of engine valves. Though they may seem small in size, these components play a crucial role in determining the engine’s overall performance, efficiency, and longevity. In this piece, we’ll delve into the fascinating world of engine valves, uncovering their purpose, mechanics, and significance in keeping your vehicle’s engine running smoothly.

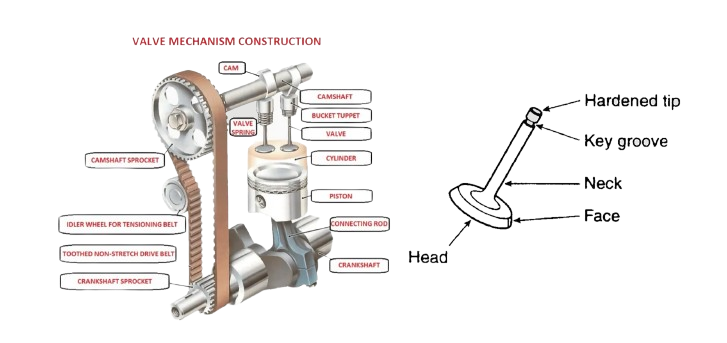

In the world of internal combustion engines, an engine valve is like a gatekeeper, controlling the movement of gases as they flow in and out of the engine’s combustion chambers or cylinders while the engine is running. An engine typically has two main types of valves: intake valves and exhaust valves.

DIFFERENT TYPES OF ENGINE VALVES

INTAKE VALVES

Intake valves are crucial components of combustion engines that allow the air-fuel combination to enter the combustion chamber. They contribute significantly to the efficiency and performance of the engine. Here are some important points about intake valves.

| Aspect | Description |

|---|---|

| Function | Intake valves help the air-fuel mixture flow into the combustion chamber from the intake manifold. |

| Location | Located at the intake port of each cylinder head. |

| Design | Usually larger than exhaust valves to make it easier for air-fuel mixture to enter. |

| Material | Crafted from robust materials such as stainless steel, frequently with finishings or processes to combat damage and high temperatures. |

EXHAUST VALVES

| Aspect | Description |

|---|---|

| Function | Exhaust valves enable the release of spent gases from the combustion chamber into the exhaust manifold. |

| Location | Located near the exhaust port of each cylinder head. |

| Design | Smaller than intake valves and made to resist higher temperatures and corrosive exhaust fumes. |

| Material | Constructed from heat-resistant materials such as Inconel, stainless steel, or other alloys with high melting temperatures. |