Piston rings are critical components in an engine, ensuring proper sealing, efficient combustion, and minimal oil consumption. Choosing the right rings and gapping them correctly is essential for optimal engine performance. There’s a wealth of knowledge that one should have about making sure that piston rings are fitted and gap-free prior to purchasing and fitting new piston rings.

There are a variety of marketplaces that allow you to purchase the most reliable piston rings. You’ll need to be aware of certain aspects about how they need to be sized prior to doing so. In this blog, we’ve talked about the best the right piston rings to fit your vehicle, and how to properly space them. Continue reading if you’re considering buying or installing piston rings.

Choosing the Right Piston Rings

Understand the Application

- Street Engines: Require durable and efficient piston rings with good sealing and wear resistance.

- Performance Engines: Need rings that withstand high pressure and temperature, such as low-tension or gapless rings.

- Industrial Engines: Prioritize longevity and resistance to extreme conditions.

Material Selection

- Cast Iron Rings: Affordable and suitable for standard engines.

- Steel Rings: Offer superior strength and durability, ideal for high-performance engines.

- Chromium or Moly-Coated Rings: Provide reduced wear and better heat dissipation.

Size and Compatibility

- Ensure the rings match the bore size and are compatible with the piston and cylinder wall material

Ring Design

- Compression Rings: Responsible for sealing combustion gases.

- Oil Control Rings: Regulate oil film on the cylinder walls.

- Choose designs like taper-faced, barrel-faced, or straight-cut depending on engine requirements.

Avoiding Common Mistakes When Filling Gapping Piston Rings

Not able to measure gaps

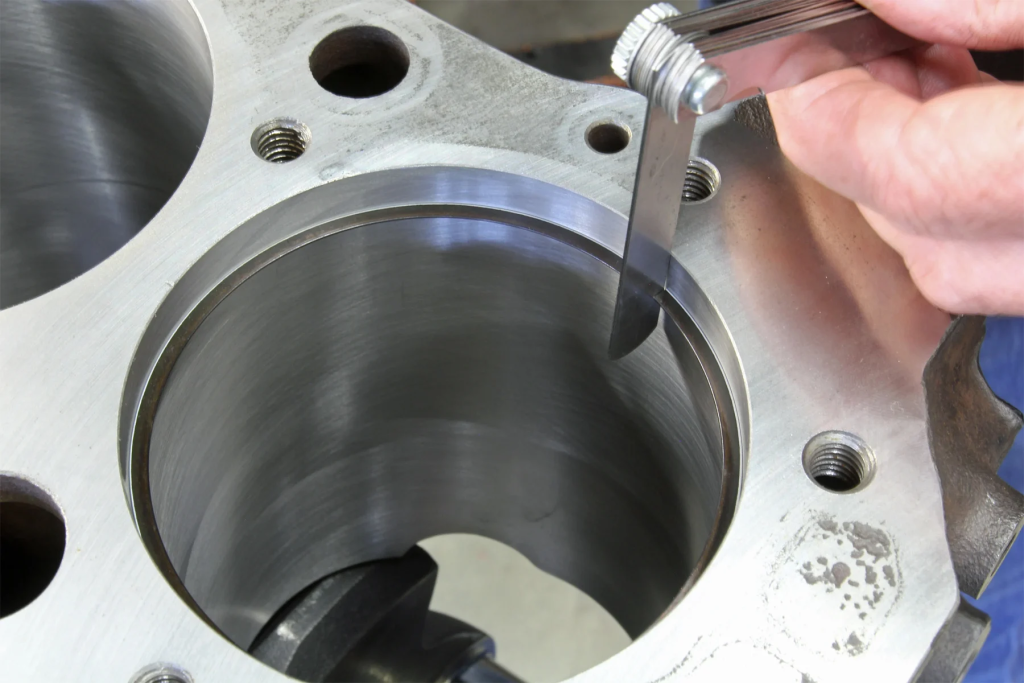

Rings can be considered to be pre-gapped and ready to install and have more room for gap than is typical between rings made by ring makers. Check that every ring has been set in the cylinder you are planning to set it in, and is measured the same way.

The ring must be affixed to the cylinder during every step of the procedure. In certain cases the cylinders may be slightly different, and you should ensure that you are consistent when installing them.

Rings pointing to the incorrect direction

There is a certain orientation for the majority of sets with top and second rings. There are many factors that can make it the case, including bends and slopes etc. Both on the second and first rings there’s typically a line or a dot which indicates the side that is facing up.

Concerning both the rings at the top on a piston, certain pistons have the same dimensions at both ends. To figure out where the rings are take into consideration the shape and purpose of each ring.

Piston Ring Installation: How to Gap Piston Rings Correctly?

There are two ways employed to set up rings. Expanders aren’t just for engineers and experts in engineering. People can also apply them by rolling them onto. When putting on rings, the most basic method is to reduce its distortion by applying gentle pressure to the ring to ensure it is held in its place. This will allow you to make sure that the piston rings are gapped correctly.

The installation of the oil ring expander starts by following the directions included in the packaging that is provided by the ring maker. Expanders shouldn’t overlap. After that, they should be handled with care. Your personal preferences can influence how piston rings are put in. The methods used to install them differ too. In the process of installation, you simply must be sure to not score the ring’s surface. You can ensure that the deed is properly executed and is appropriate by minimizing distortion and stop damage to the rings.