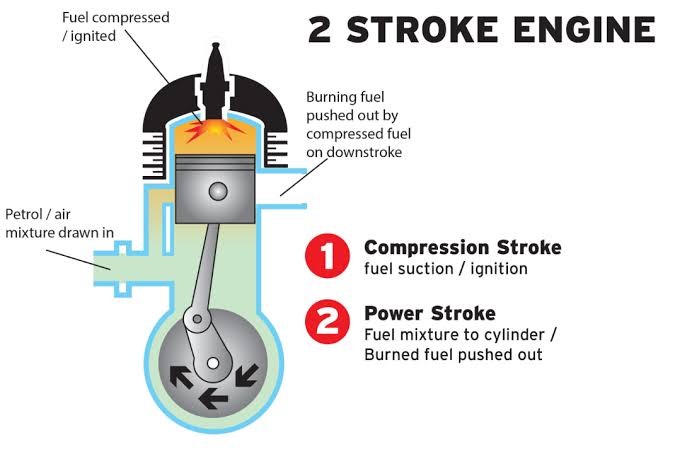

A two-stroke engine is widely used in motorcycles, marine engines, and power tools due to its compact design and high power output. This popularity can be attributed to the engine’s ability to deliver a significant amount of power relative to its size, making it ideal for applications where space and weight are critical factors. One of the most crucial components ensuring the engine’s durability and efficiency is the cylinder liner.

A two-stroke engine is widely used in motorcycles, marine engines, and power tools due to its compact design and high power output. This popularity can be attributed to the engine’s ability to deliver a significant amount of power relative to its size, making it ideal for applications where space and weight are critical factors. One of the most crucial components ensuring the engine’s durability and efficiency is the cylinder liner.

This component not only houses the piston but also experiences extreme temperatures and pressures during operation, which makes its quality and design vital to overall performance. It plays a pivotal role in maintaining proper combustion, reducing friction, and extending engine life. By providing a smooth surface for the piston to glide against, the cylinder liner minimizes wear and tear, thus enhancing the engine’s reliability and longevity.

Furthermore, the material and treatment used for the cylinder liner can significantly influence the engine’s thermal efficiency, ultimately impacting fuel consumption and emissions. Therefore, understanding the importance of the cylinder liner is essential for anyone looking to optimize the performance and sustainability of two-stroke engines.

What is a Cylinder Liner?

A cylinder liner, also known as a sleeve, is a cylindrical component placed inside the engine block to form a durable surface for the piston to move within. In a two-stroke engine, the liner is subjected to intense thermal and mechanical stress due to continuous power strokes in every revolution of the crankshaft.

Functions of a Cylinder Liner in Two-Stroke Engines

- Wear Resistance: The liner protects the engine block from direct contact with the piston, reducing wear and tear.

- Efficient Lubrication: It provides an optimal surface for lubrication, preventing excessive friction and overheating.

- Heat Dissipation: The liner helps transfer heat away from the combustion chamber, preventing thermal damage.

- Improved Compression: Ensures an airtight seal between the piston and the cylinder, enhancing engine performance.

- Corrosion Protection: Made from high-quality materials, it resists corrosion caused by fuel combustion and environmental conditions.

Types of Cylinder Liners for Two-Stroke Engines

- Wet Liners: These liners have direct contact with coolant and offer superior heat dissipation, commonly used in marine and high-performance engines.

- Dry Liners: They do not come in direct contact with coolant and rely on external heat dissipation mechanisms, making them more common in smaller engines.

- Chromed or Nitrided Liners: These have surface treatments to increase hardness and reduce friction, enhancing the engine’s lifespan.

Materials Used for Cylinder Liners

- Cast Iron: Most commonly used due to its durability and excellent thermal resistance.

- Nickel-Silicon Carbide (Ni-SiC): A high-performance coating often used in racing and premium engines.

- Aluminum Alloys: Lightweight and thermally efficient, commonly seen in modern engines.

Common Issues and Maintenance Tips

- Scuffing and Scoring: Caused by inadequate lubrication or overheating; regular oil checks and proper cooling system maintenance can prevent this. These issues often arise when the engine is not receiving sufficient oil, leading to increased friction between moving parts. This friction can create excessive heat, which exacerbates the problem and can result in serious engine damage.

- To combat this, it’s essential to establish a routine for checking oil levels and quality, as well as ensuring that the cooling system is functioning optimally. By being proactive and addressing these maintenance needs, vehicle owners can significantly reduce the risk of scuffing and scoring, ultimately prolonging the life of their engine and enhancing overall performance.

- Liner Cracks: Liner cracks are a common issue that can arise in various applications, particularly in environments subjected to extreme temperature variations. These fluctuations can cause materials to expand and contract, leading to stress and eventual cracking. To mitigate this risk, it is crucial to invest in high-quality materials that are specifically designed to withstand such thermal extremes.

- By selecting materials with superior thermal stability and durability, one can significantly enhance the longevity and performance of the liner. Additionally, implementing proper installation techniques and regular maintenance can further contribute to minimizing the occurrence of liner cracks. Ultimately, a proactive approach can safeguard against costly repairs and ensure the integrity of the system in the long run.

- Excessive Wear: Excessive wear is a common issue that develops gradually over time due to constant use and exposure to various operating conditions. As components within the engine experience repeated friction and stress, they begin to degrade, leading to diminished performance. Therefore, it is crucial to monitor the condition of these parts regularly.

- Timely replacement of worn components not only prevents potential breakdowns but also ensures that the engine operates at its optimal efficiency. By addressing wear proactively, vehicle owners can extend the lifespan of their engines and maintain reliable performance over the long term.

Real-World Application: Cylinder Liners in Marine Engines

The above image showcases large two-stroke engine cylinder liners used in marine engines. These liners are essential in ship propulsion systems, where durability and efficient heat dissipation are critical. Their robust construction, featuring cooling passages and precision machining, ensures optimal performance in harsh maritime environments.

Conclusion

Cylinder liners are indispensable in two-stroke engines, ensuring smooth operation, enhanced durability, and improved performance. Investing in high-quality liners and maintaining them properly can significantly extend an engine’s lifespan. Whether in motorcycles, marine vessels, or industrial machinery, the right cylinder liner makes all the difference.

For premium-quality two-stroke engine cylinder liners, explore Quintess International’s range of durable and high-performance solutions tailored to meet the industry’s needs.