Cylinder liners play a crucial role in the operation of engines. They are integral to the performance and longevity of engines across various industries.

Understanding the different types of cylinder liners and their applications is essential. It helps in making informed decisions when choosing the right liner for specific needs.

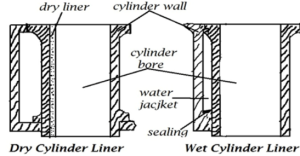

This article delves into the world of cylinder liners. It explores the two main types: wet and dry liners, and their unique characteristics.

We will also discuss the materials used in their manufacture. The importance of these materials’ properties, such as thermal conductivity and wear resistance, will be highlighted.

The article further explores the applications of these liners in different types of engines. From diesel to petrol, and even gas engines, cylinder liners have a significant role.

Join us as we navigate the fascinating world of cylinder liners. Gain insights into their importance in engine efficiency, maintenance, and the future trends in cylinder liner technology.

Understanding Cylinder Liners

Cylinder liners, or sleeves, form a vital component of engine architecture. They are cylindrical barriers fitted within the engine block, playing a pivotal role in housing the pistons as they move. This action is fundamental in facilitating efficient combustion processes within an engine.

Their primary function includes creating a durable and high-resistance surface for the piston and rings. They help in maintaining the engine’s structural integrity under the immense pressure and temperature created during operation. These liners bear the brunt of repetitive cycles, therefore preventing direct wear on the engine block itself.

The Role of Cylinder Liners in Engine Performance

Cylinder liners are crucial for engine performance and longevity. They ensure smooth piston motion by providing a consistent surface, reducing friction between the piston rings and the cylinder wall. This reduction in friction minimizes wear and prolongs the life of the engine.

Additionally, cylinder liners facilitate effective heat transfer from the combustion chamber to the engine’s cooling system. This heat dissipation is essential to prevent overheating and maintain optimal engine efficiency. By enhancing heat management, cylinder liners contribute significantly to improved engine reliability and performance.

Wet Cylinder Liners: Features and Benefits

Wet cylinder liners are in direct contact with the engine coolant, providing excellent cooling capabilities. This direct contact improves heat dissipation, making them suitable for large engines like those in ships and power plants. They are removable, which simplifies replacement and maintenance compared to other types.

One of the main advantages of wet cylinder liners is their efficient cooling. Here are some benefits of wet cylinder liners:

- Enhanced Cooling: Direct contact with coolant facilitates superior heat transfer.

- Ease of Replacement: Their design allows for straightforward removal and installation.

- Ideal for Large Engines: Suitable for high-performance applications and large-scale engines.

Dry Cylinder Liners: Characteristics and Advantages

Unlike wet liners, dry cylinder liners do not contact the engine’s coolant directly. They are pressed or shrunk into the engine block, offering a more compact design. Dry liners are often used in smaller engines, such as those found in cars and light trucks.

This type of liner is known for its simplicity and cost-effectiveness. Some key advantages include:

- Compact Design: Fits seamlessly into the engine block without additional seals.

- Cost-Effective: Often less expensive due to a simpler installation process.

- Durability: Offers reliable performance in smaller, less demanding engine applications.

Material Considerations for Cylinder Liners

The materials used in cylinder liners play a crucial role in their performance and durability. Common materials include cast iron and steel, valued for their wear resistance and strength. These materials contribute significantly to the liner’s ability to withstand high temperatures and pressures.

Material properties like thermal conductivity are also essential. They ensure efficient heat dissipation, preventing engine overheating. Advances in material technology, such as composites, are pushing the boundaries of cylinder liner performance. Selecting the right material ensures the liner not only matches the engine’s needs but also enhances overall efficiency.

Heat Dissipation and Lubrication in Cylinder Liners

Cylinder liners are crucial for effective heat management in engines. They help transfer excess heat away from the combustion chamber. This heat dissipation prevents engine components from overheating, safeguarding engine performance and longevity.

Additionally, cylinder liners play a vital role in lubrication. They support the movement of piston rings with a thin film of oil, reducing friction and wear. Proper lubrication is essential for maintaining engine efficiency and preventing mechanical failures. By balancing heat dissipation and lubrication, cylinder liners contribute significantly to the smooth operation of engines.

Cylinder Liners and Engine Noise Reduction

Cylinder liners also contribute to reducing engine noise. By dampening vibrations from pistons, they minimize sound levels during operation. This noise reduction enhances the comfort within vehicles and industrial settings. By selecting quality cylinder liners, manufacturers can achieve a quieter and more pleasant engine experience for users.

The Manufacturing Process of Cylinder Liners

The production of cylinder liners involves several precise steps. Initially, materials like cast iron or steel are selected based on required properties. The casting process shapes these materials into rough cylinder forms.

Post-casting, liners undergo machining to achieve exact specifications. Machining ensures dimensional accuracy and a smooth surface finish. Both these aspects are crucial for optimal fitting and performance. Quality control tests follow to guarantee durability and reliability. This rigorous process ensures cylinder liners meet industry standards and perform efficiently in various engine types.

Applications of Different Types of Cylinder Liners

Cylinder liners find diverse applications across numerous industries. Their usage depends on the engine type and specific performance needs. Recognizing which liner suits a particular application aids in maximizing engine efficiency and lifespan.

Various sectors employ cylinder liners, including:

- Marine industry for large ship engines

- Automotive sector for both diesel and petrol engines

- Power plants needing robust liners for high-performance generators

- Manufacturing requiring liners in heavy machinery

- Racing and performance vehicles benefiting from bespoke solutions

Each type of cylinder liner is selected based on its unique characteristics, ensuring compatibility with its intended application. Understanding these applications can guide in choosing the appropriate liner type for different engine models and operational demands.

Future Trends and Innovations in Cylinder Liner Technology

The future of cylinder liner technology looks promising, with an emphasis on enhancing performance and sustainability. Research is focused on developing composite materials that offer improved wear resistance and reduced weight. These materials contribute to increasing engine efficiency and lowering fuel consumption.

Another notable trend is the integration of advanced coatings to extend the lifespan of liners. These coatings improve surface hardness and reduce friction between moving parts. Moreover, digital tools and simulations are being used to optimize liner design, ensuring precision in production. These advancements aim to meet the evolving demands of modern engine applications.

Conclusion: Selecting the Right Cylinder Liner

Selecting the right cylinder liner is crucial for optimal engine performance and longevity. Consider factors like material type, engine application, and maintenance requirements. Understanding these elements helps ensure your engine runs efficiently and remains reliable over time. Making informed choices about cylinder liners benefits both performance and cost-effectiveness.